Industrial pizza bases are rarely identical. Size variation, random shapes and small shifts on the conveyor make it hard to apply sauce with consistent weight and a clean edge.

FoodJet’s pizza sauce depositor applies liquid pizza sauces accurately on every base—without mechanical alignment. Our vision system detects each pizza individually and adapts the depositing pattern to the product contour. That means consistent coverage, repeatable weight control and less manual intervention, even at high line speeds.

Designed for liquid products. Typical applications include tomato sauce, pesto and other liquid toppings (e.g., honey). Not suitable for solid toppings such as shredded cheese or diced vegetables.

Want to discuss your pizza line requirements? We’ll help you choose the right setup (pattern, edge-free zone, throughput and cleaning concept).

Do you want to discuss your specific pizza sauce application case?

Pizza sauce depositor

If you cover your products with pizza sauce, you face typical challenges such as products of varying shapes and misaligned products. FoodJet's pizza sauce applicator was engineered to tackle precisely those problems.

FoodJet’s vision-guided depositor tracks each pizza on the conveyor and adjusts the depositing path in real time. This compensates for positional variation and random shapes, so you get consistent coverage and a clean edge without mechanical alignment.

How it works

FoodJet designs and builds pizza sauce depositors to improve industrial pizza lines. The system applies liquid sauces accurately and consistently, reducing manual handling and improving repeatability. Other advantages of our pizza sauce depositing machines are:

Vision-guided depositing for random shapes and positional variation

Repeatable weight control for consistent coverage per pizza (configuration-dependent)

Edge-free patterns via software-defined depositing paths

Adaptive pattern follows the product contour (no mechanical alignment)

High-throughput capability for industrial lines

FoodJet creates pizza sauce depositing machines tailored to your production line, reducing reliance on manual labour and improving consistency. Our unique depositing technology ensures efficiency and precision in every step of your pizza manufacturing process.

How to clean an industrial pizza sauce machine?

All of our pizza sauce machines are engineered for industrial environments. You can easily clean the depositor of any sauce residues. The software includes an automatic cleaning program that runs through multiple cycles. You do not have to dismantle any mechanical parts to successfully get your system ready for the next shift.

Advanced vision technology

FoodJet uses a camera system to detect and inspect the pizza bases on most of our sauce applicators, including the automatic pizza depositor. Whether you need statistical information on your production throughput or you want to be in charge of quality, the vision technology helps you improve your production. In combination with the servo-driven pumps, weight control is achievable even with variations in pizza crust shape and size. The equipment handles high production speeds even if the pizza sauce has to be applied to pizza crusts that have a different form.

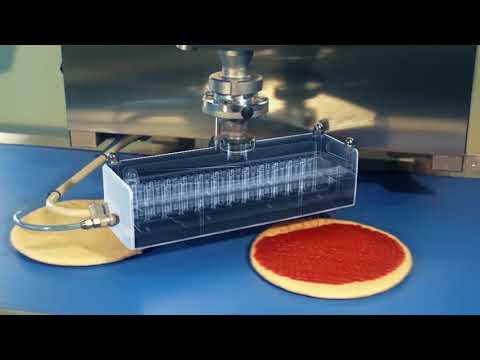

Pizza depositor video

This video gives you a good impression of FoodJet's pizza sauce depositing quality. Let us show you our automatic pizza depositor in action:

Check out videos

Check all videosFoodJet's depositing solutions

The depositing solutions of FoodJet are always tailor-made to suit the needs and wishes of your production process. This means that no machine is exactly the same! This allows us to manufacture depositing solutions for a wide range of depositing materials. Take a look at our similar applications:

Butter on sandwiches

Even butter layers for a smooth texture and great taste